Product description

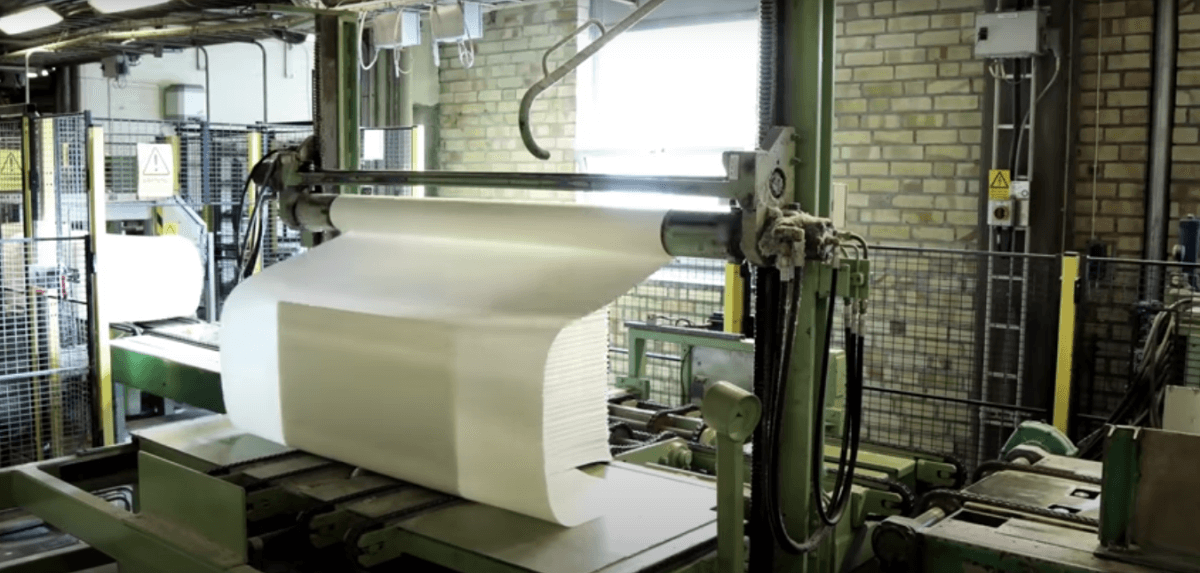

Hippocampus OU sale high purity cellulose has proven its excellence over many years in highly demanding applications such as pharmaceutical tablets, usage castings, and filaments.

Our high purity cellulose is obtained from softwood. Our advanced process delivers cellulose easily reprocessed and with viscosity to meet your requirements.

Our cellulose is bleached in a unique, totally chlorine-free, closed-loop bleach plant, producing cellulose of high brightness.

Our cellulose has a consistent quality and high reactivity, enabling users to reduce chemical consumption and processing time.

We offer individual customer service and quality throughout the entire business.

Our customer adapted products match highly set demands on product quality as well as secure deliveries and sustainability.

The main field of application is viscose for fashion and textiles. But cellulose can also be found in many other products, such as medical tablets, food, sausage casing, tires, and paint.

What these have in common are high standards regarding cleanliness and functionality.

The main field of application is viscose for fashion and textiles. But cellulose can also be found in many other products, such as medical tablets, food, sausage casing, tires and paint.

What these have in common are high standards regarding cleanliness and functionality.

Cellulose for viscose staple fiber

Cellulose for viscose staple fiber is the foundation of our sales, a quality with solid and reliable characteristics. The coniferous trees’ long fibers give the product its special properties that fit very well in the manufacture of viscose staple fiber, a natural material with nice comfort features. Cellulose is also used in cellophane, sponges, and as an important component in the paint. The cellulose’s consistent quality contributes to an efficient production at our customers, irrespective of the process used for further refining.

Cellulose for viscose filament

Sometimes extraordinary cellulose is needed. Hippocampus OU offers highly refined cellulose with very high and consistent quality. It is designed for applications that require exceptionally pure cellulose, commonly in viscose. As a customer, you can find it in beautiful, silk-like fashion garments. Other fields of application are technical cord and acetate. The cellulose is customized to satisfy all our customers’ requirements. The unique properties, combined with great technical expertise and highly developed customer collaboration, makes it the obvious choice for customers who want the best.

Cellulose for casings

The latest addition to the cellulose product family is the newly developed Cellulose Ultra.

It has been developed through genuine laboratory and factory trials.

Ultra is suitable for use in the manufacture of casings (including sausage skin) where the purity requirements are very high.

This high-quality product is expected to reach more use in the future.

More applications

Some application sectors have exceptionally high requirements on cleanliness, e.g. medicine, food and hygiene. Our cellulose is a self-evident choice here as well.

It meets the FDA requirements and in order to provide customer security, we gladly show our process with chlorine-free and closed-loop bleaching, as well as our high-quality supply chain.

When the cellulose leaves the production line it is safe to consume.

It is used for production of micro crystalline cellulose, an extremely pure cellulose powder contained in medicine tablets and in food.

Another important field of application is sausage casing production, where high requirements on cleanliness also are essential.

Since cellulose is good for digestion it is often used as a moisture and texture agent in diet drinks and juices.

We offer high purity softwood cellulose in five quality specifications.

Which can be viewed below.

Quality specification: high purity softwood cellulose #2100

Sheet properties |

Quality 2100 |

Test method |

| Shee weight, g/m2 | 935 | ISO 536:1995 |

| Apparent density, g/cm3 | 0,7 – o,8 | ISO 534:2005 |

| Moisture,% | 7±1 | ISO |

| Cleanliness, numb./kg* | <70* | Internal |

| *Notis no bark or shives | ||

Cellulose characteristics |

||

| Brightness, % ISO | >92 | ISO 2470:1999 |

| Viscosity, ml/g | 510-560 | ISO 5351:2004 |

| Aceton extractives, % | 0,15-0,20 | SCAN-CM 49:03 |

| R 18%, insoluble fraction in 18% NaOH, % |

>95 | ISO 699:1982 |

| Ash, % | <0,1 | ISO 1762:2001 |

| SiO2, mg/kg | <50 | Internal |

| Ca, mg/kg | <450 | SCAN-CM 38:05 |

| Fe, mg/kg | <2,0 | SCAN-CM 38:05 |

| Mn, mg/kg | <0,4 | SCAN-CM 38:05 |

| Mg, mg/kg | <250 | SCAN-CM 38:05 |

| Contains 1,5 kg/ton surfactant (Visco 388) | ||

| * o,15% acetone extractives comes from Visco 388 | ||

Quality specification: high purity softwood cellulose #2150

Sheet properties |

Quality 2150 |

Test method |

| Shee weight, g/m2 | 935 | ISO 536:1995 |

| Apparent density, g/cm3 | 0,7 – o,8 | ISO 534:2005 |

| Moisture,% | 7 | ISO |

| Cleanliness, numb./kg* | <40* | Internal |

| *Notis no bark or shives | ||

Cellulose characteristics |

||

| Brightness, % ISO | >92 | ISO 2470:1999 |

| Aceton extractives, % | <0,05* | SCAN-CM 49:03 |

| R 18% | >95 | ISO 699:1982 |

| R 10% | >90 | ISO 699:1982 |

| Alpha-cellulose,% | >92 | TAPPI 203 |

| pH | 7 | Internal |

| Ash, % | 0,10 | ISO 1762:2001 |

| SiO2, mg/kg | 50 | Internal |

| Ca, mg/kg | 35 | SCAN-CM 38:05 |

| Fe, mg/kg | 1,5 | SCAN-CM 38:05 |

| Mn, mg/kg | 0,2 | SCAN-CM 38:05 |

| Water-soluble substances, % | <0,25 | Internal |

| Heavy metals (Pb,Cd, and more), ppm | <10 | SCAN-CM 54 |

| Dissolves completely in copper-ethylenediamine hydroxide. | ||

| *Due to TCF bleached no chlorinated sticky resin, and no debonding agent added | ||

Quality specification: high purity softwood cellulose #2162

Sheet properties |

Quality 2162 |

Test method |

| Shee weight, g/m2 | 935 | ISO 536:1995 |

| Apparent density, g/cm3 | 0,7 – o,8 | ISO 534:2005 |

| Moisture,% | 7±2 | ISO |

| Cleanliness, numb./kg* | <70* | Internal |

| *Notis no bark or shives | ||

Cellulose characteristics |

||

| Brightness, % ISO | >92 | ISO 2470:1999 |

| Viscosity, ml/g | 520-580* | ISO 5351:2004 |

| Aceton extractives, % | ≤0,15 | SCAN-CM 49:03 |

| R 18% | ≥96 | ISO 699:1982 |

| R 10% | ≥91 | ISO 699:1982 |

| Alpha-cellulose,% | ≥93 | TAPPI 203 |

| Ash, % | ≤0,10 | ISO 1762:2001 |

| SiO2, mg/kg | ≤50 | Internal |

| Ca, mg/kg | ≤50 | SCAN-CM 38:05 |

| Fe, mg/kg | ≤2,0 | SCAN-CM 38:05 |

| Mn, mg/kg | ≤0,4 | SCAN-CM 38:05 |

| *The viscosity can be adjusted within the limits of 450-650 ml/g. Indicative values tested at more research. The cellulose can be delivered with or without any rebounding agent added |

||

Quality specification: high purity softwood cellulose #2200

Sheet properties |

Quality 2200 |

Test method |

| Shee weight, g/m2 | 935 | ISO 536:1995 |

| Apparent density, g/cm3 | 0,7 – o,8 | ISO 534:2005 |

| Moisture,% | 7 | ISO |

| Cleanliness, numb./kg* | <200* | Internal |

| *Notis no bark or shives | ||

Cellulose characteristics |

||

| Brightness, % ISO | >91,5 | ISO 2470:1999 |

| Viscosity, ml/g | 540* | ISO 5351:2004 |

| Viscosity, cP | 18 | |

| DP (Degree of Polymerization) | 780 | |

| Aceton extractives, % | 0,10 | SCAN-CM 49:03 |

| R 18% | ≥94 | ISO 699:1982 |

| R 10% | 88 | ISO 699:1982 |

| Alpha-cellulose,% | 91 | TAPPI 203 |

| Ash, % | 0,12 | ISO 1762:2001 |

| SiO2, mg/kg | 50 | Internal |

| Ca, mg/kg | 450 | SCAN-CM 38:05 |

| Fe, mg/kg | 2,0 | SCAN-CM 38:05 |

| Mn, mg/kg | 0,2 | SCAN-CM 38:05 |

| Mg, mg/kg | 250 | SCAN-CM 38:05 |

| *The viscosity can be adjusted within the limits of 450-650 ml/g. Indicative values tested at more research. The cellulose can be delivered with or without any rebounding agent added |

||

Quality specification: high purity softwood cellulose #2230

Sheet properties |

Quality 2230 |

Test method |

| Shee weight, g/m2 | 935 | ISO 536:1995 |

| Apparent density, g/cm3 | 0,7 – o,8 | ISO 534:2005 |

| Moisture,% | 8±2 | ISO |

| Cleanliness, numb./kg* | <100* | Internal |

| *Notis no bark or shives | ||

Cellulose characteristics |

||

| Brightness, % ISO | >91,5 | ISO 2470:1999 |

| Viscosity, ml/g | 510-560 | ISO 5351:2004 |

| Viscosity, cP | 14,9-17,7 | |

| DP (Degree of Polymerization) | 715-793 | |

| Aceton extractives, % | 0,08 | SCAN-CM 49:03 |

| R 18% | ≥94 | ISO 699:1982 |

| R 10% | 88 | ISO 699:1982 |

| Alpha-cellulose,% | 91* | TAPPI 203 |

| Ash, % | 0,12 | ISO 1762:2001 |

| SiO2, mg/kg | 45 | Internal |

| Ca, mg/kg | 35 | SCAN-CM 38:05 |

| Fe, mg/kg | 1,5 | SCAN-CM 38:05 |

| Mn, mg/kg | 0,2 | SCAN-CM 38:05 |

| Mg, mg/kg | 220 | SCAN-CM 38:05 |

| *Alfa is not measured regularly as part of our process control. The cellulose will be delivered with 1 kg/ton rebounding agent added (Visko 388) |

||

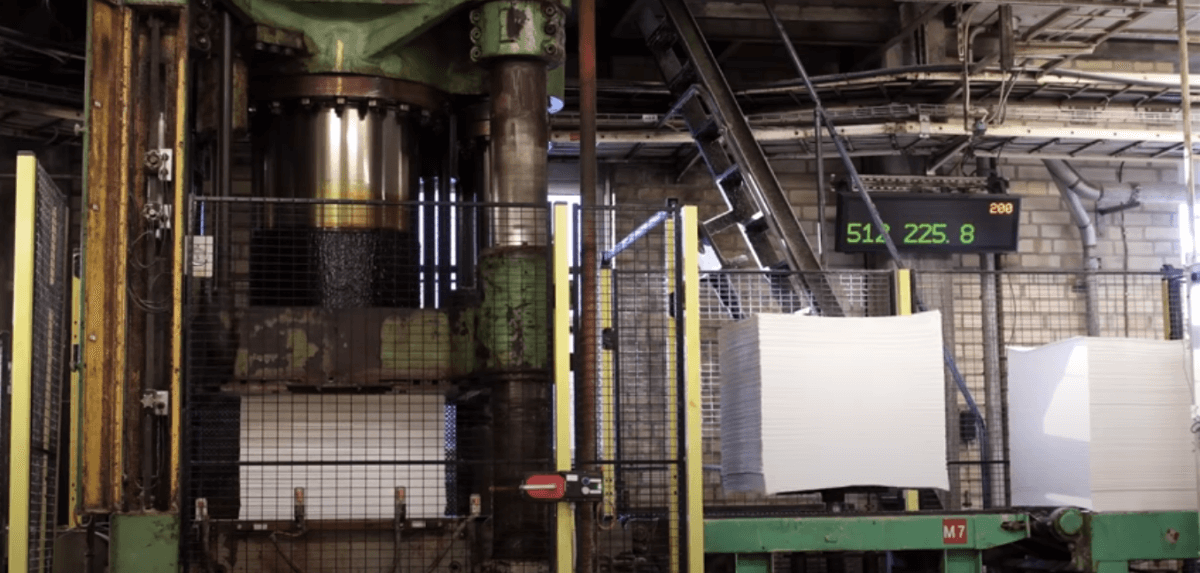

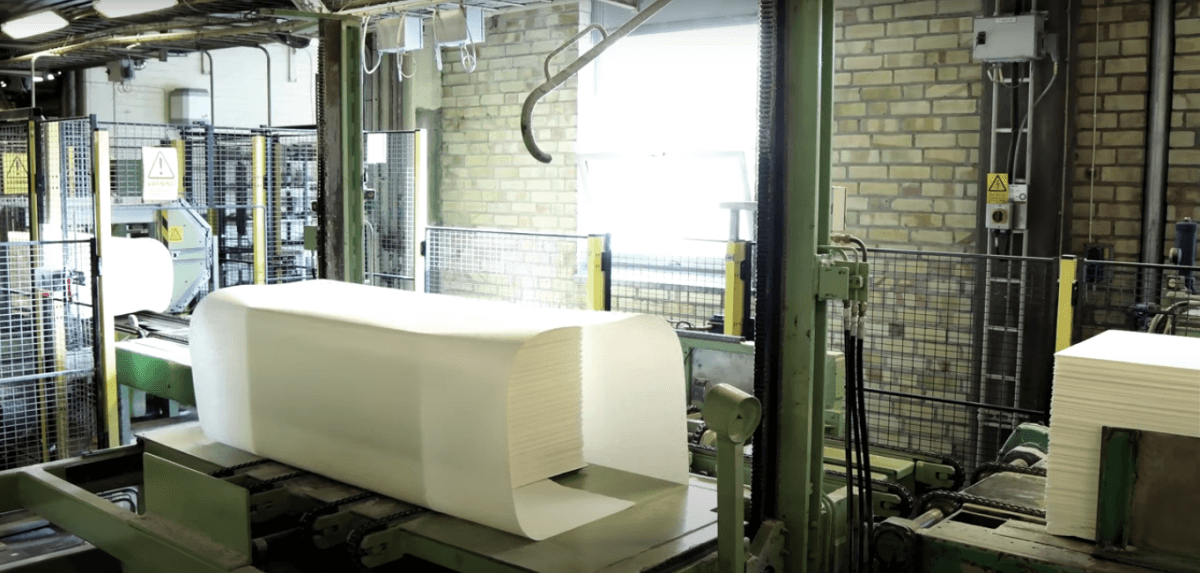

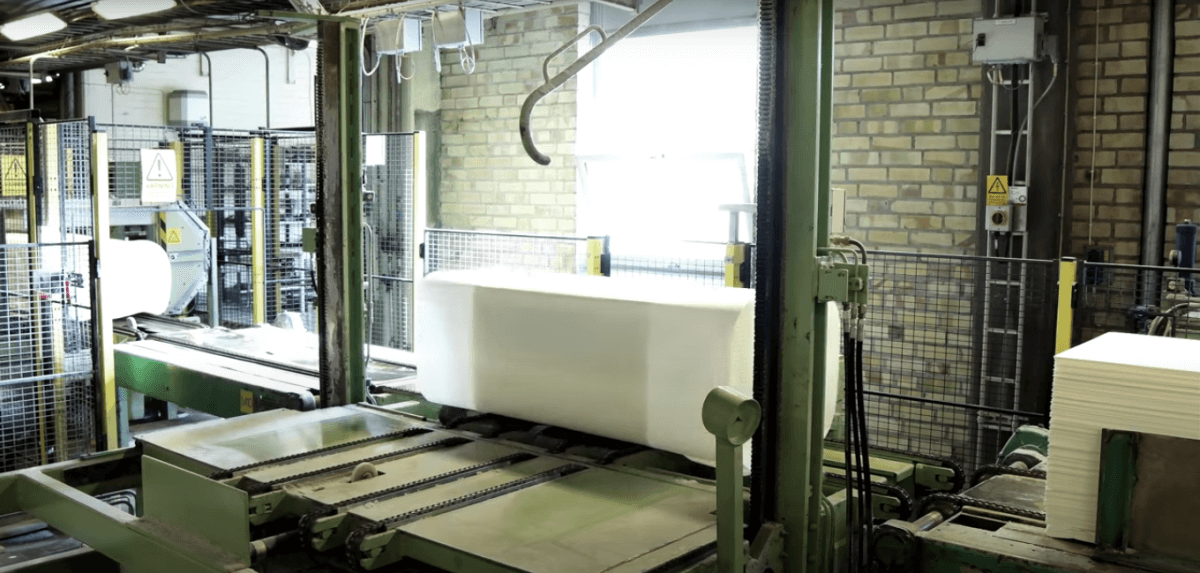

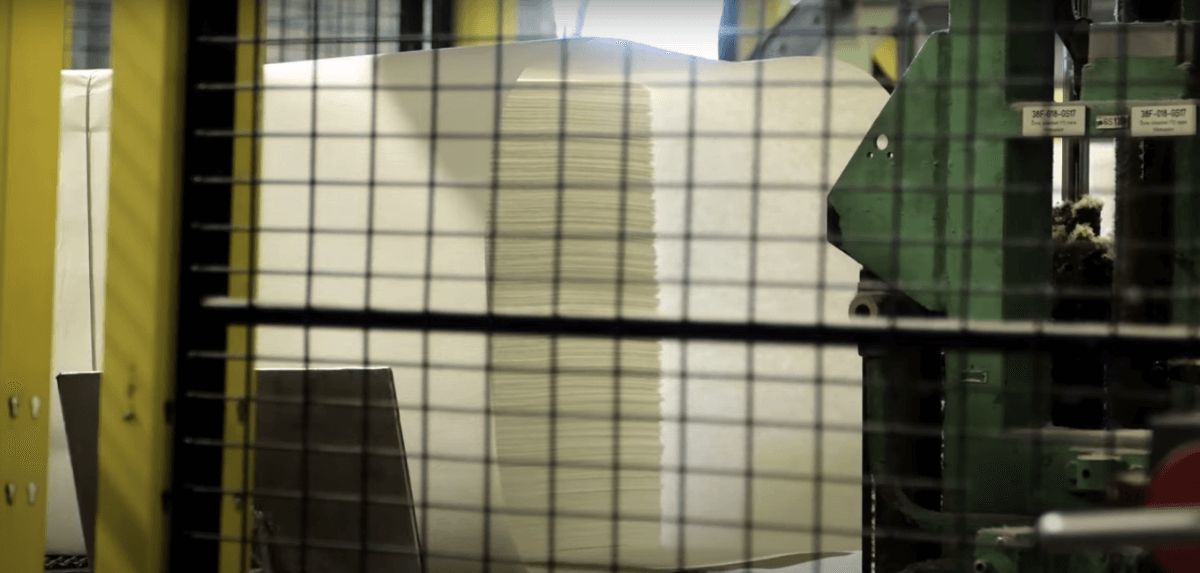

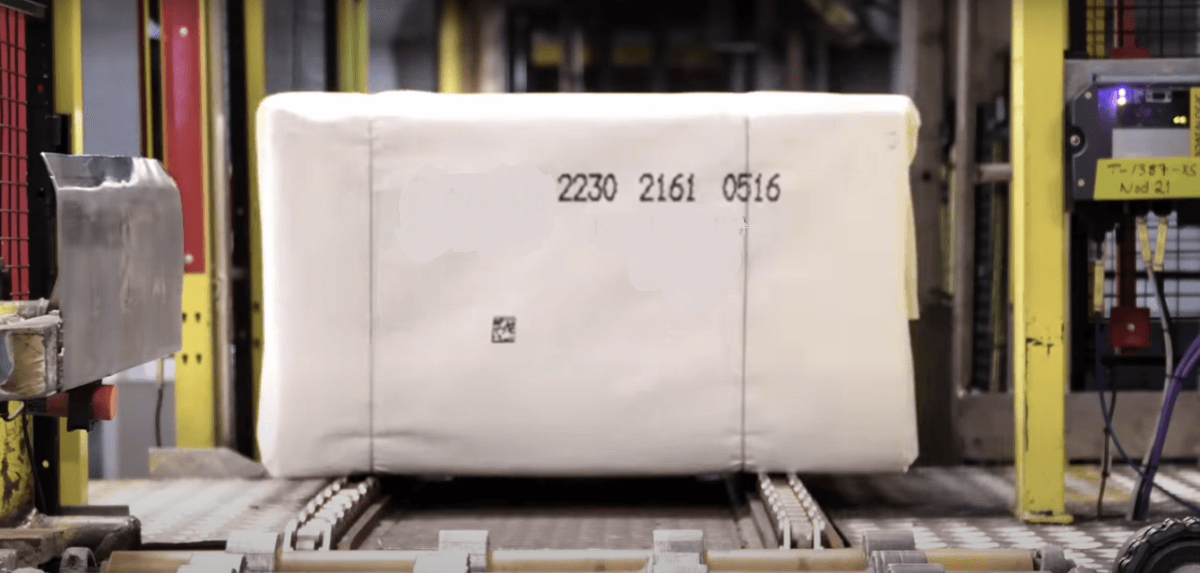

Packing description

Sheet dimension

600x800mm

Bale unit dimension

Length 1200 mm

Width 800 mm

Height 1500 mm

Wire dimension 3 mm

Breaking Load 6867

NTensile strength 970 N/mm2

Six lifting wires per unit

Bale dimension

Lenght 800 mm

Width 600 mm

Height 500 mm (max)

Wire dimension 2,3 mm

Breaking load 3530

NTensile strength 850 N/mm2

Bale weight 232,5 kg*

*Air dry (90% dry content)

Bale weight225 kg B/L

Wrapping

– Paper wrapping

– Unwrapped

On request we can do

We can supply various types of wood cellulose.

Ask Your Question

WhatsApp:

+ 372 581 788 67

e-mail:

sales@hippocampus.ee