CCA Type-C 60% Wood Preservative

- CAS #37337-13-6

- HS CODE: 3808.92.95

- MOLECULAR FORMULA: AS2CRCUO9

- PRODUCT NAME: OXIDE CCA-C 60% TYPE C, PASTE

- CHEMICAL NAMES: CCA-C; COPPER ARSENATE, CHROMATED; HSDB 7705;

ARSENIC ACID (H3ASO4), COPPER(2+) SALT (2:3), CHROMATED; - Minimum order quantity: 20 MT (One 20″ container)

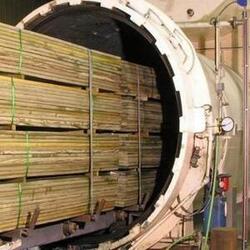

We supply CCA Type-C Wood Preservative 60% in form of paste, density 1,8-1,9 kg/m3, diluted in cold water at ratio 1:40.Product name: CCA Type-C Wood Preservative 60%, paste

Manufacturer’s instruction on paste dilution: For wood pressure treatment CCA paste to be diluted in cold water in the ratio 1:40 (one part of CCA paste to 40 parts of cold water). Thus, one drum of 48-50 liters (net weight 90kg) is dissolved in 2000 liters of cold water. From one 50-liter drum of CCA paste - 2050 liters of treating (working) solution is obtained.

Consumption at autoclaving 100 liters of treating (working) solution to 1 m3 of wood.

ELEMENTAL CONCENTRATION IN 20G/L TREATING SOLUTION OF PRESERVATIVE:

Oxide CCA 60% Paste is the copper-chromium-arsenic mixture in the form of paste. When the paste is diluted in ratio 1:40 of cold water the elemental concentrations of copper, chromium and arsenic in the treating solution of preservative complies with the data given in Table #1:

| Active Element | Concentration (g/L) as per COA | Concentration (g/L) as per standard SANS 673:2008 |

| Cu | 1,68 | 1,61 – 1,99 |

| Cr | 2,96 | 2,74 – 3,11 |

| As | 2,76 | 2,32 – 2,93 |

| Total | 7,4 | Minimum 7,3 |

SANS673:2008, Clause 3.2.

OXIDE CONCENTRATIONS IN OXIDE CCA 60% PASTE:

| Oxide form | Concentration (%, m/m) | Concentration (%,m/m) |

| CuO | 10,50 | 9 – 11 |

| CrO3 | 28,40 | 22 – 29 |

| As2O5 | 21,10 | 21 – 26 |

| Total | 60 |

Note: Total oxide concentration shows 60% as stipulated on our Oxide CCA 60% Paste label and MSDS

In order to check compliance of Oxide CCA 60% Paste (as per COA results) with the American Wood Protection Association (AWPA) standards, the oxides concentration as per COA (60%) are converted to a 100% oxide basis:

| Oxide form | AWPA specifications | Concentration of Oxide CCA 60% Paste, as 100% oxide basis, (%, m/m) |

| CuO | 17.0% – 21.0% | 17,5 |

| CrO3 | 44.5% – 50.5% | 47,33 |

| As2O5 | 30.0% – 38.0% | 35,17 |

| Total | 100 |

| Active Element | Elemental Concentration (g/L) | Elemental Concentration (g/kg) |

| Cu | 1,68 | 84 |

| Cr | 2,96 | 148 |

| As | 2,76 | 138 |

&

| Oxide form | Concentration (%) | Concentration (%) as 60% oxide basis |

| CuO | 17,50 | 10,5 |

| CrO3 | 47,33 | 28,4 |

| As2O5 | 35,17 | 21,1 |

The concentrations listed above may vary according to the limits stipulated in the standards’ requirements listed above, accordingly.

Chromated Copper Arsenate (CCA) is a wood preservative, a copper-chromium-arsenic mixture produced in the form of paste, or a liquid. The mixture is diluted in accordance with the manufacturer’s instructions to give the treating solution a nominal total elemental concentration of copper, chromium and arsenate of 7,3 g/l. A 7,3 g/L total elemental concentration treating solution is equivalent to a 20 g/L solution of a preservative where the copper, chromium and arsenic are expressed as copper sulphate pentahydrate, sodium dichromate dehydrate and arsenic pent oxide dehydrate, respectively.

CCA is the world’s most widely used wood preservative. It is manufactured to national and international standards depending on the country of intended use, including AWPA P23-10 for the USA and SANS 673 for South Africa, TU 2499-001-78576072-2009 for Russia and each manufacturer complies with these standards.

Ask Your Question

WhatsApp:

+ 372 581 788 67

e-mail:

sales@hippocampus.ee